Home

Welcome to NVision, Inc - 3d Scanning Solutions

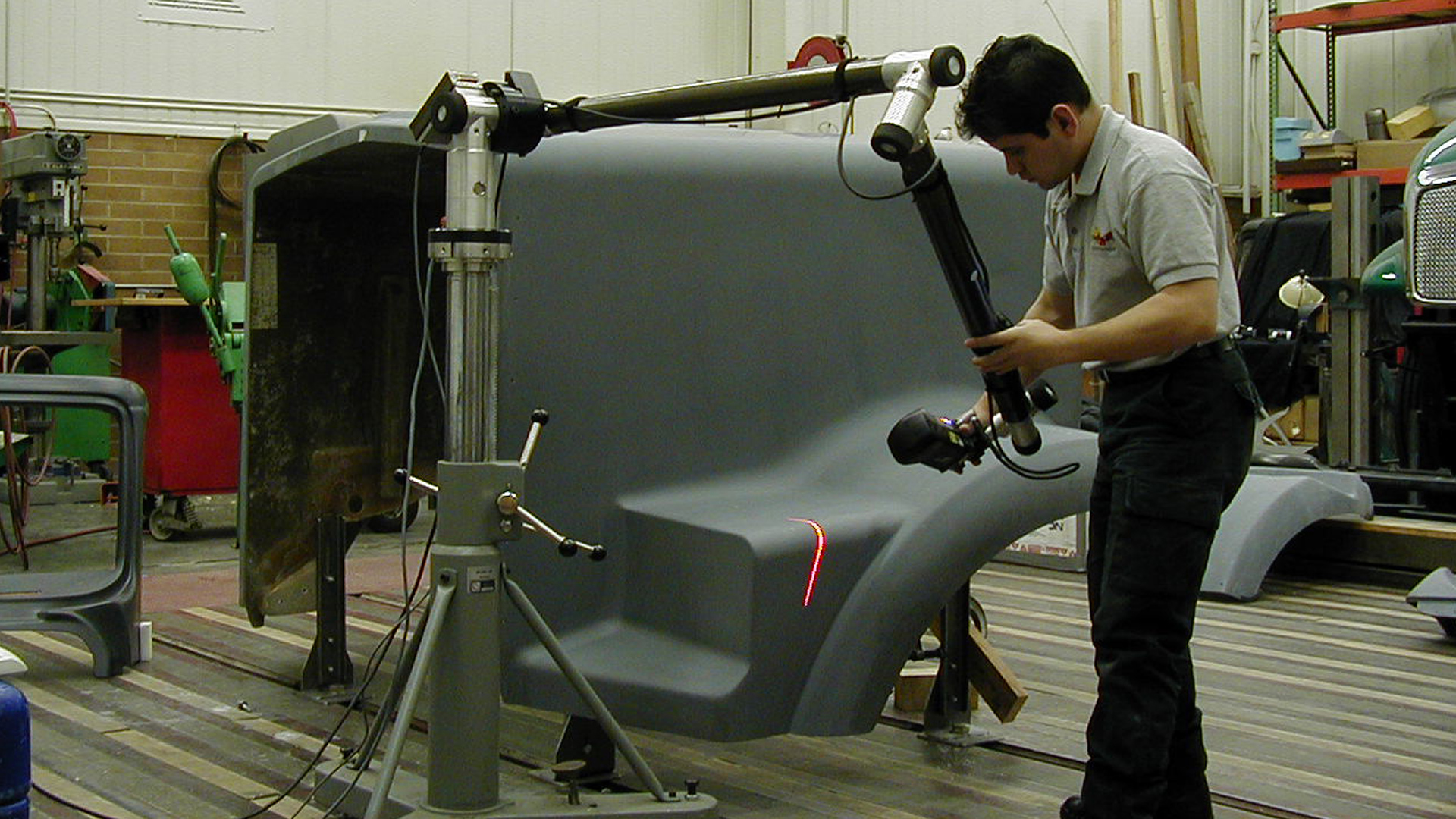

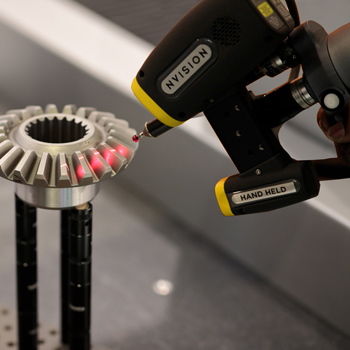

YES! We do 3D Non-contact Scanning, Measurement, Inspection, Reverse Engineering...and more. For over 30 years, our engineering services have helped a diverse array of clients, including Boeing, Toyota, and the U.S. military, achieve even the most complex engineering goals. As the USA’s most experienced scanning professionals, we know our business...and yours too.

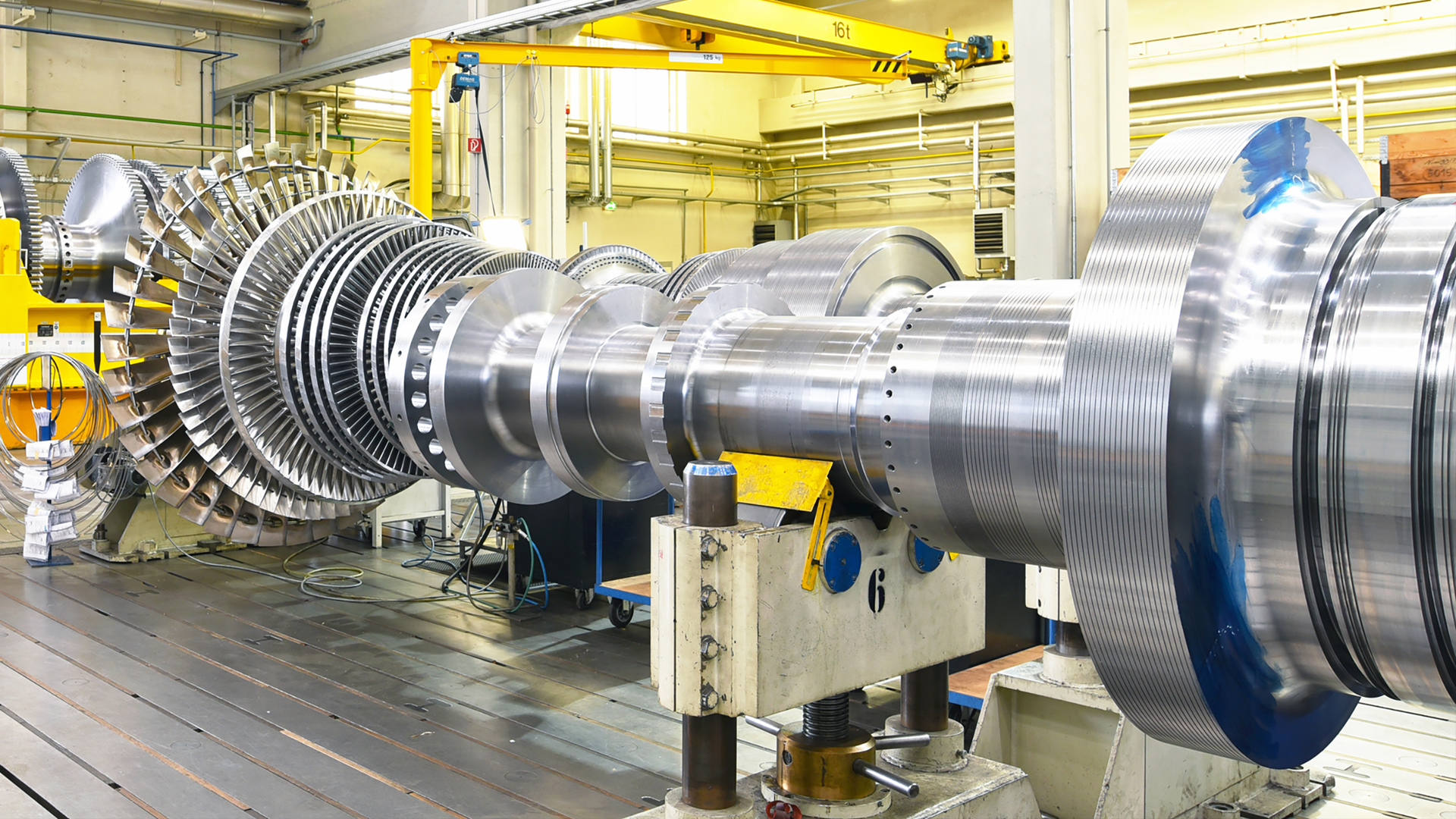

Our 30+ years of 3D scanning is extensive, spanning nearly every industry -- from automotive and aerospace to medical and power generation; from oil/gas and military/defense to marine design and art preservation; from building construction to fossil replication. Our experience shows...in the results we deliver and the customers we keep.

Articles

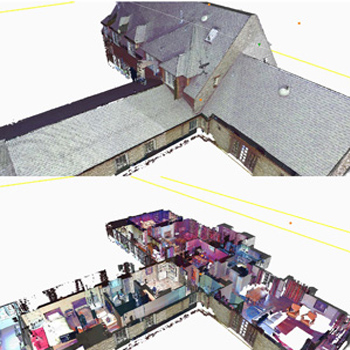

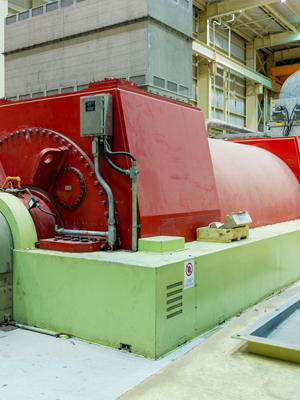

NVision's comprehensive plant scanning and engineering solutions offer significant enhancements for power plant project managers. By broadening your range of deliverable solutions, our services empower you with a distinct competitive edge.

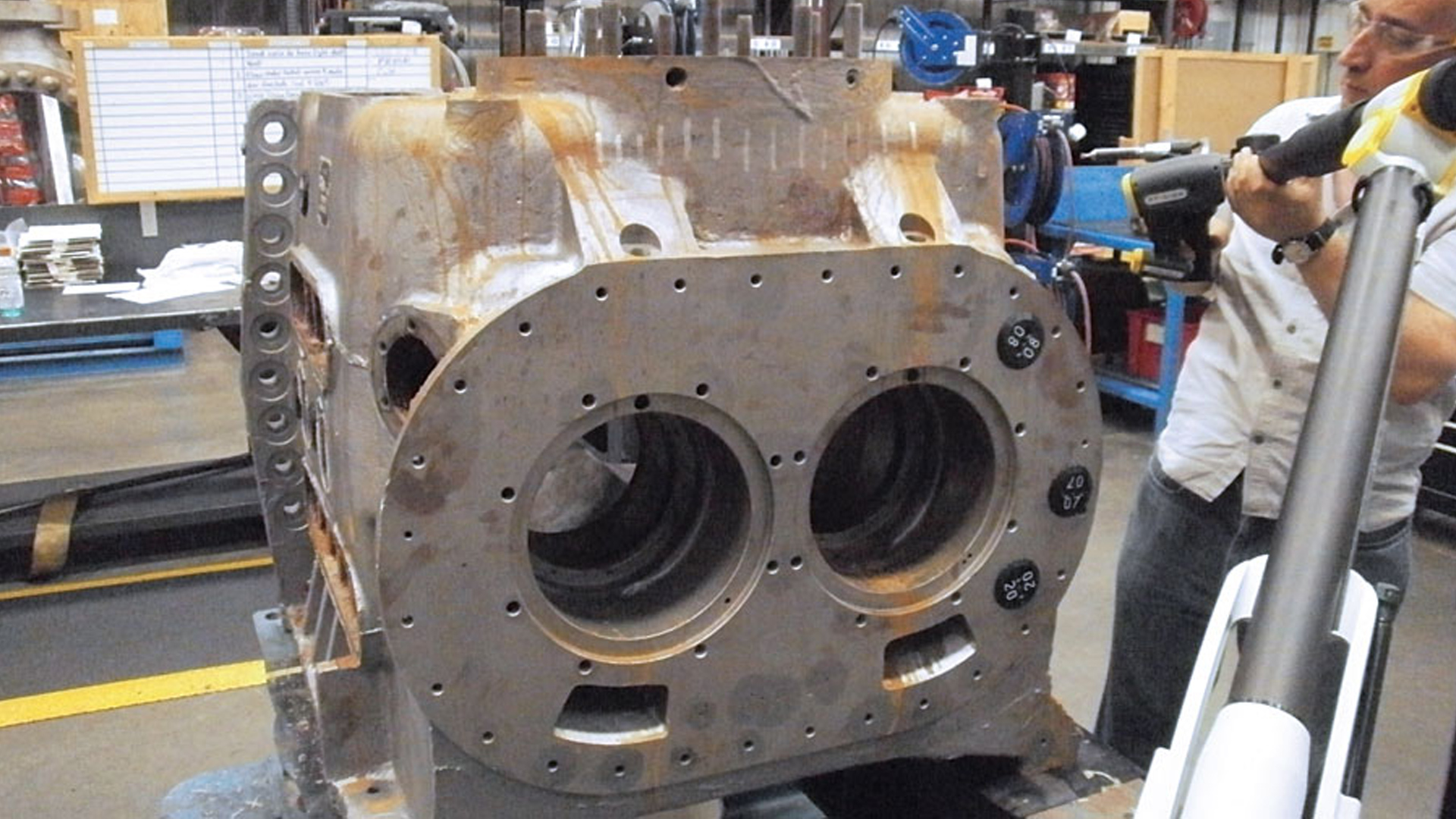

When a leading aerospace company faced the challenge of replicating critical components without original design documentation, it turned to NVision, Inc. (Southlake, TX). NVision provides complete reverse engineering, encompassing 3D scanning, CAD modeling, 2D drawings, and materials analysis.

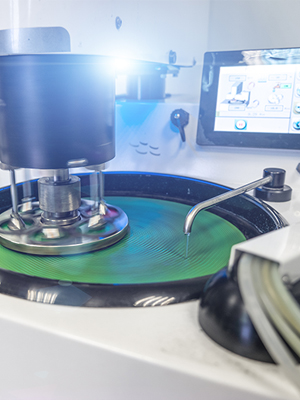

The science and technology of 3-D measurement has evolved dramatically in recent decades. Accordingly, a wide range of industries continue to adopt 3-D scanning as a key tool for ensuring optimal quality of manufactured goods, reverse engineering and other related processes.

NVision Inc.’s engineering services help coal-fired power plants that are converting to natural gas quickly determine optimal locations for installing updated instrumentation.

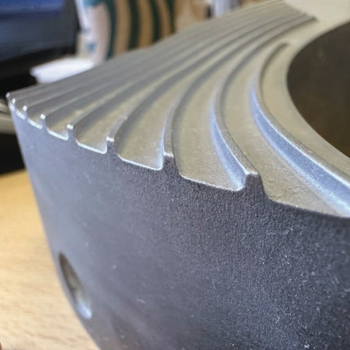

Bringing a highly accurate Airsoft replica to market often involves long development cycles and complex tooling workflows. For Soft Air USA®, traditional mold-based methods were stretching timelines and adding unnecessary cost and risk.