Aiming for Excellence: How NVision’s 3D Laser Scanning Helped Soft Air USA® Cut Three Months from Replica Development

Bringing a highly accurate Airsoft replica to market often involves long development cycles and complex tooling workflows. For Soft Air USA®, traditional mold-based methods were stretching timelines and adding unnecessary cost and risk. Turning to NVision’s engineering-grade 3D laser scanning and CAD modeling services, the company compressed development time by months while also improving accuracy.

Introduction

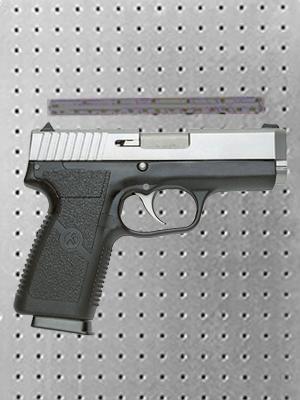

Soft Air USA, a leader in licensed Airsoft (replica firearm) products, faced the challenge of bringing a new FNP-series handgun replica to market quickly while maintaining dimensional fidelity and surface detail.

“We wanted to make as accurate a reproduction of the gun as is humanly possible,” said John Steele, President of Soft Air USA®.

Traditionally, the company produced replicas by making silicone molds of real firearms and using those molds to create injection tooling that, in turn, produced replica Airsoft guns.

Over time, however, this workflow became increasingly inefficient and time-consuming for several reasons:

- The firearm used as the master was typically rendered unusable during the molding process

- Silicone molds often contained imperfections—such as air bubbles—that required extensive manual correction

- Physical molds had to be shipped to contract manufacturers in Asia, increasing lead times and logistical costs

To address these challenges, Soft Air USA® partnered with NVision to apply high-precision 3D laser scanning and CAD modeling to replica production—reducing development time by approximately three months, improving accuracy, and delivering a digital, production-ready CAD model that could be quickly and securely shared with manufacturing partners overseas.

Ultimately, adopting the scan-to-CAD process shortened time-to-market and supported increased sales for the new replica.

NVision’s laser scanning and CAD modeling services helped Soft Air USA® get its replica Airsoft guns to market much faster than was possible using previous methods

From Manual Molding to Digital Workflows

NVision’s non-contact 3D laser scanning and CAD modeling workflow replaced the physical mold process entirely.

Engineers used high-resolution laser scanning, carefully sweeping a laser line across the firearm’s surfaces while cameras triangulated its changing profile to digitally capture the complete external geometry.

The resulting point cloud—containing millions of surface measurement points defining the gun’s shape—was used to create a fully parametric CAD model that accurately reproduced the geometry of the original firearm. This digital master was transmitted electronically, eliminating shipping delays and enabling efficient design iteration with manufacturing partners overseas.

Engineering-Grade Precision and Dimensional Fidelity

The laser scanner used by the NVision team captures up to 60,000 discrete spatial measurements per second with a tolerance of ±0.025 mm (25 microns), or approximately one-thousandth of an inch. For reference, the average human hair measures about 70 microns in diameter.

This level of measurement fidelity supports the creation of CAD models that preserve fine surface features and complex geometry, contributing to dimensional consistency and repeatability in the final replica.

By reducing the need for manual mold correction, Soft Air USA® improved quality control and allowed engineering teams to focus more on design refinement and product development.

“The digital file produced by NVision duplicated the details of the original gun with exceptional fidelity,” said Steele. “The result was a much more accurate replica than we were ever able to produce using silicone molds.”

Results: Faster Time-to-Market and Competitive Advantage

By adopting a fully digital scan-to-CAD workflow, Soft Air USA®:

- Reduced development time by approximately three months

- Achieved higher levels of dimensional fidelity compared to prior mold-based methods

- Enabled faster, more efficient collaboration with overseas production partners

“Laser scanning helped us get our products to market faster, which resulted in increased revenue generated by each product,” said Steele.

The project illustrates how modern 3D scanning and CAD modeling workflows can help manufacturers streamline product development and support positive commercial outcomes in competitive markets.

The CAD model produced by NVision’s laser scanning was used to create the most accurate replica possible

Conclusion

NVision’s engineering-grade 3D scanning and CAD modeling services help manufacturers accelerate product development, reduce rework, and maintain design integrity.

For companies producing Airsoft replicas, sporting goods, or other highly detailed consumer products, digital scanning workflows offer a practical path to faster development cycles, improved consistency, and stronger market performance.

“NVision’s digitization engineering services helped us get this new product to market sooner than would have been possible using our previous methods,” Steele concluded. “It also enabled us to achieve a higher level of dimensional fidelity, helping us deliver a better product more efficiently. They made it easy and cost-effective to take advantage of laser scanning’s benefits without making any capital investment.”

Note:

“Airsoft” refers to a category of replica firearms that shoot lightweight plastic pellets, typically at velocities well below those of traditional firearms. Airsoft products are widely used for recreational and training purposes when operated in accordance with applicable field rules and with appropriate protective equipment, particularly eye protection.

Interested in accelerating your next product launch?

Learn how NVision’s 3D laser scanning and CAD modeling services help manufacturers reduce development time, improve accuracy, and bring products to market faster—without capital investment.