NVision Helps Orthodontic Supplier Recalibrate Cone-Beam CT Scanner

Driven to Innovate - The Lonely Pursuit of Innovation - Podcast with Steven Kersen and Ethan Vickery

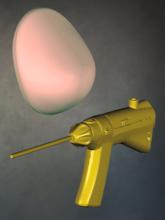

Aiming for Excellence: How NVision’s 3D Laser Scanning Helped Soft Air USA® Cut Three Months from Replica Development

Bringing a highly accurate Airsoft replica to market often involves long development cycles and complex tooling workflows. For Soft Air USA®, traditional mold-based methods were stretching timelines and adding unnecessary cost and risk. Turning to NVision’s engineering-grade 3D laser scanning and CAD modeling services, the company compressed development time by months while also improving accuracy.

Introduction

NVision's 3D Scanning Expertise Accelerates Breast Implant and ENT Device Design

NVision Helps Hamar Build Perfect-Fit Roof Racks Faster

A bird-damaged Boeing 737 returns to service in 48 hours

Swift work by NVision, Inc., a leader in 3D non-contact optical scanning/measurement for more than 29 years, helped a major U.S. airline quickly repair a bird-damaged Boeing 737 wing and return the restored jet back to flight in just two days. The rapid turnaround helped the airline avoid the financial losses typically incurred by grounding aircraft.

NVision 3D Scanning Helps Army Depot Get Aircraft Back in the Skies Faster

NVision’s 3D scanning and reverse engineering services are helping a U.S. Army aviation maintenance depot cut the time required to reverse-engineer rotary-wing aircraft components from weeks to hours. Previously, the depot used a coordinate measuring machine (CMM) to capture the numerous data points needed to define the complex geometry of structural aircraft components.

NVision’s 3D Scanning Helps Major Aerospace Manufacturer Achieve First-Time-Fit Precision

A major aerospace manufacturer needed to ensure its accessories would fit aircraft exteriors and interiors accurately on the first installation. By turning to NVision’s 3D scanning and reverse-engineering services, the company captured exact aircraft geometries rapidly and with aerospace-grade precision—achieving first-time-fit accuracy, cutting costly rework, and improving flight-performance modeling.

NVision Hits the Right Note: Featured in Manufacturing Engineering & Technology and the Advanced Carbons Council

One-Stop Shop: NVision's Comprehensive Reverse Engineering and Expanded Metallurgy Services Draws Rave Reviews

When a leading aerospace company faced the challenge of replicating critical components without original design documentation, it turned to NVision, Inc. (Southlake, TX). NVision provides complete reverse engineering, encompassing 3D scanning, CAD modeling, 2D drawings, and materials analysis. Leveraging its advanced scanning/measurement, engineering, and metallurgy capabilities, NVision delivered a complete solution that ensured top-to-bottom replication accuracy.