NVision Helps Orthodontic Supplier Recalibrate Cone-Beam CT Scanner

Problem: Verifying CT Scanner Accuracy for Orthodontic Applications

NVision, Inc., a leader in 3D non-contact optical scanning for more than 35 years, recently helped a dental supplier recalibrate its in-house cone-beam computed tomography (CBCT) scanner by providing an independent, high-accuracy physical reference model.

NVision provided an orthodontic supplier with high-accuracy optical scanning to recalibrate its CBCT scanner, eliminating circular validation errors. By using metrology-grade laser scanning as a neutral external reference, NVision ensured accuracy, compliance, and repeatability—improving diagnostic precision and regulatory standing.

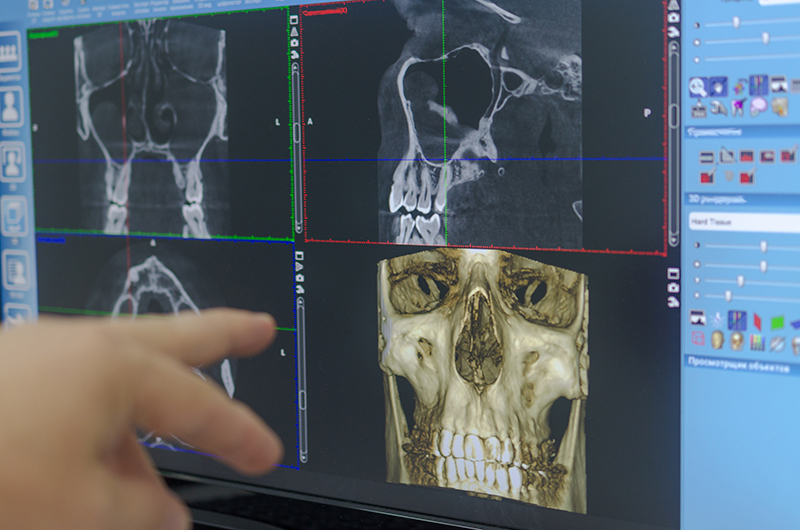

CBCT scanner used in dental and orthodontic imaging.

Image: JohnHGood41, CC BY-SA 4.0, via Wikimedia Commons

(https://creativecommons.org/licenses/by-sa/4.0)

The supplier faced a common but critical challenge in orthodontic imaging: how to verify the dimensional accuracy of a CBCT system used to generate detailed 3D representations of human anatomy. Accurate verification is essential for ensuring quality patient treatment, maintaining internal quality assurance programs, meeting regulatory expectations, and enabling reliable digital workflows.

CBCT scanning has become increasingly common in orthodontics because it provides a high-resolution, three-dimensional view of the skull, teeth, roots, and jaw that cannot be achieved with traditional 2D X-rays. These scans support diagnosis and personalized treatment planning—but their clinical value depends entirely on the accuracy of the underlying measurement data.

To validate its system, the orthodontic supplier required a trusted, high-precision external reference that was independent of the CBCT scanner itself.

Solution: NVision’s Independent, Metrology-Grade Optical Scanning

The supplier engaged NVision’s Engineering Service Division to generate an ultra-accurate 3D model of a human skull. The physical skull was sent to NVision, where engineers used a metrology-grade handheld laser scanner to capture its external geometry.

The objective was to produce a traceable, repeatable digital reference model that could serve as a benchmark for verifying and recalibrating the CBCT system. NVision’s scan data provided the precise dimensional information required to recalibrate the CBCT scanner to the highest achievable level of accuracy.

How NVision Solved the Problem

NVision’s handheld laser scanner is designed for metrology-grade measurement and is capable of capturing complex 3D geometry from objects of nearly any size or shape. As an NVision engineer expertly guides the scanner around the object, it rapidly captures high-resolution surface data with exceptional accuracy and speed, producing stable, repeatable results suitable for calibration and validation workflows.

Intuitive software supports full model editing, polygon reduction, and data export to standard CAD, inspection, and metrology software platforms.

By using non-contact optical scanning rather than radiographic imaging, NVision was able to produce a highly accurate physical reference model that was fully independent of the CT system being tested. This independence is critical for imaging system validation, as it eliminates circular measurement errors—situations in which a system is effectively verified using data derived from the same measurement method or equipment.

“Our scan of the skull confirmed that the orthodontic company’s CBCT machine, although only 1/1000 of an inch off in its measurements, required recalibration,” says Colin Ellis, Engineering Manager at NVision. “The company then used our measurements as the primary reference throughout the recalibration process.”

Physical skull (left) and 3D computer model generated from NVision’s metrology-grade laser scan data (right).

Why Neutral, External Measurement Matters

Circular validation occurs when a measurement system is checked using reference data generated by the same system or the same underlying measurement physics. In imaging applications, this can create false confidence and mask systematic errors.

For example, scanning a skull with a CBCT system, generating a 3D model from that CT data, and then using that same model to verify scanner accuracy is circular validation. It only confirms that the system agrees with itself—not that it is accurate.

- NVision avoided circular validation by using:

- Non-contact optical laser scanning

- A different measurement physics (light rather than X-rays)

- A separately calibrated metrology system

- Independent measurement and verification workflows

This enabled a valid comparison between CBCT-derived measurements and an external optical reference, with NVision serving as a neutral measurement authority rather than simply a service provider.

Measurement Stability and Repeatability

Rather than focusing solely on the CBCT’s hardware performance, NVision’s approach emphasized measurement stability and repeatability. Using its calibrated, metrology-grade laser scanning system, NVision captured the skull’s measurements multiple times and produced consistent, non-drifting results.

This repeatable dataset provided the orthodontic supplier with a stable external reference that could be trusted throughout the recalibration process. Compared with CBCT-based or contact measurement methods—such as coordinate measuring machines (CMMs) or articulated arm probes—NVision’s optical scanning delivered fast turnaround, exceptional accuracy, and an independent reference dataset.

Outcome

This project demonstrates how NVision helps orthodontic suppliers, medical device manufacturers, and imaging system users and developers validate and improve measurement accuracy. By combining advanced laser scanning technology with decades-long metrology expertise, NVision delivers independent, high-confidence, high-accuracy measurement solutions that directly support quality, compliance, and patient care.