Handheld Scanner — 3D Laser Scanner Mounted On A Portable CMM

The HandHeld scanner is the Swiss army knife of scanning devices, a remarkably versatile scanning device that is capable of rapidly capturing complex 3D geometry from almost any object, large or small. Attached to a mechanical arm that moves about the object, the scanner quickly captures data with an extremely high degree of resolution. As the object is inspected, the scanner generates, at a rate of 60,000 points per second, a point cloud consisting of millions of points, each with x,y,z coordinates and i,j,k vectors. These points comprise an exact duplicate of the object’s surface, down to the most minute detail. An optional tripod provides our technicians with complete portability in the field. The HandHeld’s intuitive software allows full model editing, polygon reduction, and data output to all standard 3D packages. The computer-aided design (CAD) file we provide captures your object in 3D from all angles, enabling accurate measurements for inspection, reverse engineering, re-design, and production.

A revolutionary portable scanner, the HandHeld’s usefulness extends to all industries--from aerospace and automotive to medical/dental and power generation; from military/defense and homeland security to consumer goods. Paleontology and the arts have also discovered the HandHeld scanner--more and more, we’re asked to scan irreplaceable fossils as well as equally priceless sculpted works on display throughout the world.

A revolutionary portable scanner, the HandHeld’s usefulness extends to all industries--from aerospace and automotive to medical/dental and power generation; from military/defense and homeland security to consumer goods. Paleontology and the arts have also discovered the HandHeld scanner--more and more, we’re asked to scan irreplaceable fossils as well as equally priceless sculpted works on display throughout the world.

Features and Benefits

- Flexible

From consumer goods to full size automobiles, the applications are unlimited. In aviation alone, the HandHeld has accurately captured the geometry of components of dramatically varying sizes and shapes; from extremely small sensors for USAF planes to the wing ribs of Boeing 737s to the much larger exteriors of aircraft. All objects of different sizes and dramatically different geometries and all accurately scanned by the HandHeld. - Portable

We can bring the scanner to your facility, making it an ideal solution for both styling studio and factory floors with equipment that can’t be easily transported like turbine assemblies. - Fast

Wide Stripe Technology enables the HandHeld to scan at 3 times the speed of previous narrow stripe technologies. This can dramatically reduce the time needed to measure complex shapes from weeks to hours. That will get your product to market faster, your legacy part installed more quickly, and accelerate reverse engineering, redesigns, repairs, and production. The accurate scans produced by the HandHeld can also save you time by eliminating unnecessary production steps. One aeronautical customer created a distorted cast and determined that it would have to recast it at a time/money cost of two months and $5,000, significantly delaying the delivery of the finished product. Using the HandHeld scanner, we accurately captured the geometry of the distorted casting, which was imported into software that made it possible to compare the actual geometry of the casting to the original solid model expressing the design intent. The software automatically oriented the distorted part to minimize differences with the design intent while also highlighting the remaining differences. This made it easy to correct the distortion during the normal machining process and ship the product to the customer on time. No time was lost and recasting was not necessary. - Non-Contact

Ideally suited to measuring soft or delicate materials such as foam, cloth or rubber, or any fragile objects, including priceless sculptures, artifacts and fossils. - Scans shiny surfaces without coating

- Speaking of non-contact, the HandHeld has the ability to scan shiny surfaces, including machined finishes, without the need to first apply a coating. Many conventional laser scanners have difficulty scanning shiny machined surfaces because the surface scatters the laser beam. Scanner operators avoid this problem by spraying the scanned surface with a non-reflective coating, but spraying is not allowed in many situations. The HandHeld doesn’t have this limitation. It can scan the shiniest medical instruments, bottles, or other consumer products without needing to first coat the surface.

- Superior accuracy

- Customer benchmarks consistently confirm the quality of the HandHeld scanner data to be superior to other non-contact technologies.

- Inspection and Defect Analysis

- The HandHeld scanner’s integrated suite of inspection tools enables us to deliver full surface models of scanned components together with deviation data to highlight any differences between the as-manufactured parts and the original design intent. Plus, the CAD models created--exact digital duplicates--of your parts and equipment can be viewed in 3D virtual form, allowing for easy inspection, measurement, comparison, and reverse engineering.

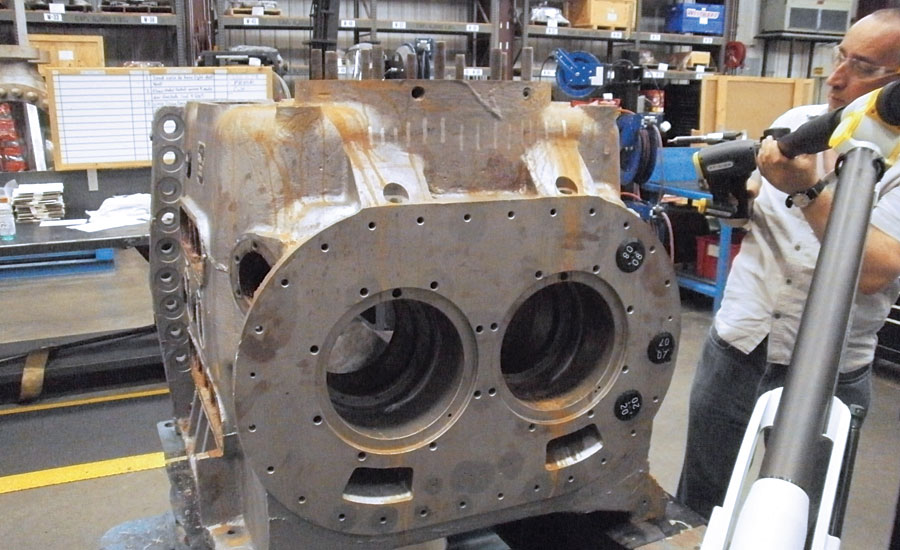

An NVision technician scanning a section of housing with a handheld laser scanner. A handheld scanner measures an object’s 3D coordinates quickly, with a high degree of resolution and accuracy.

Please contact us by phone (817.416.8006) or email (sales@nvision3d.com) to discuss your 3D Scanning/Measurement needs.