Oil and Gas

3D non-contact optical scanning (eg, laser scanning) has become an essential technology for the oil and gas Industry. No matter where your company lies in the processing chain--whether you’re an OEM, or engaged in Upstream, Midstream or Downstream operations, NVision's 3D scanning can provide significant, and time and money-saving, results at any point in the oil & gas process.

NVision's high resolution non-contact 3d laser scanning provides the fastest and most accurate method to obtain the most precise details about the shape, size, and dimensional variances of any part, structure, or facility, large or small.

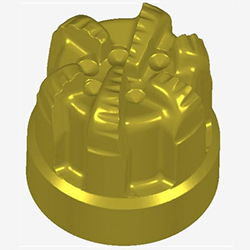

Are you an OEM for the oil and gas industry? NVision technicians can measure and reverse-engineer oil extraction and ground-engaging tools of virtually every shape and size. Our scan data can confirm whether replacement parts will fit existing equipment.

We can also help you increase the performance and life of your products by gaining a clearer picture of erosion patterns on your tools. Your engineers can use the CAD file we provide to redesign the part to improve its geometry, tolerance, and functionality.

Our engineering services will enable you to build, repair, and replicate aging legacy parts, as well as tools, dies or molds. Often, the CAD data for older parts doesn't exist. That's not a problem. We can scan legacy parts and provide you with a CAD file that perfectly replicates every detail of the part's as-is dimensions.

Ultimately, we help OEMs produce a better product, extend the life of their tools, reduce cycle times, speed part certification, reduce cycle times, and save time and money.

Are you an Upstream company?

NVision can conduct a 3D terrain survey of a proposed Upstream (or Downstream site). The resulting models can then be used to determine building feasibility, and develop terrestrial and/or nautical charts and reports.

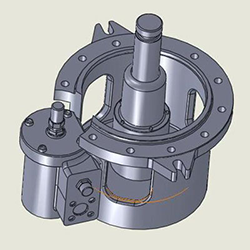

NVision can reverse-engineer any and all parts--large or small--for your oil exploration equipment.

We also scan rigs and other large structures to create precise virtual models of the structures.

Are you a Midstream company?

At NVision, we are experienced in scanning large structures such as pipelines and related infrastructure necessary to move the source material to Downstream processing facilities. This includes pumping stations, rail tank cars, tank trucks, and much more.

Are you a Downstream company?

NVision’s scans can aid in the development of refineries and other facilities. Our scanned measurements can provide the physical data necessary for asset management activities and plant modeling.

We also perform scans of large facilities undergoing expansion, which can reveal any areas of architectural/construction clashes or interferences. If these are not discovered before construction begins, such interferences can result in costly construction delays. NVsion’s engineering services let you know about potential problems or other construction anomalies BEFORE construction begins.

The above is only a partial list of the many services we provide to the oil and gas industry. For over 30 years, the NVision name has been synonymous with quality work. Our experience in the oil and gas industry shows...in the results we deliver and the customers we keep. Our clients in oil and gas include Hallibuton, Gardner Denver, Pioneer Natural Resources and other industry leaders.

Please contact us by phone (817.416.8006) or email (sales@nvision3d.com) to discuss your 3D Scanning/Measurement needs.

|

|

|

|

|

|

|

|

|